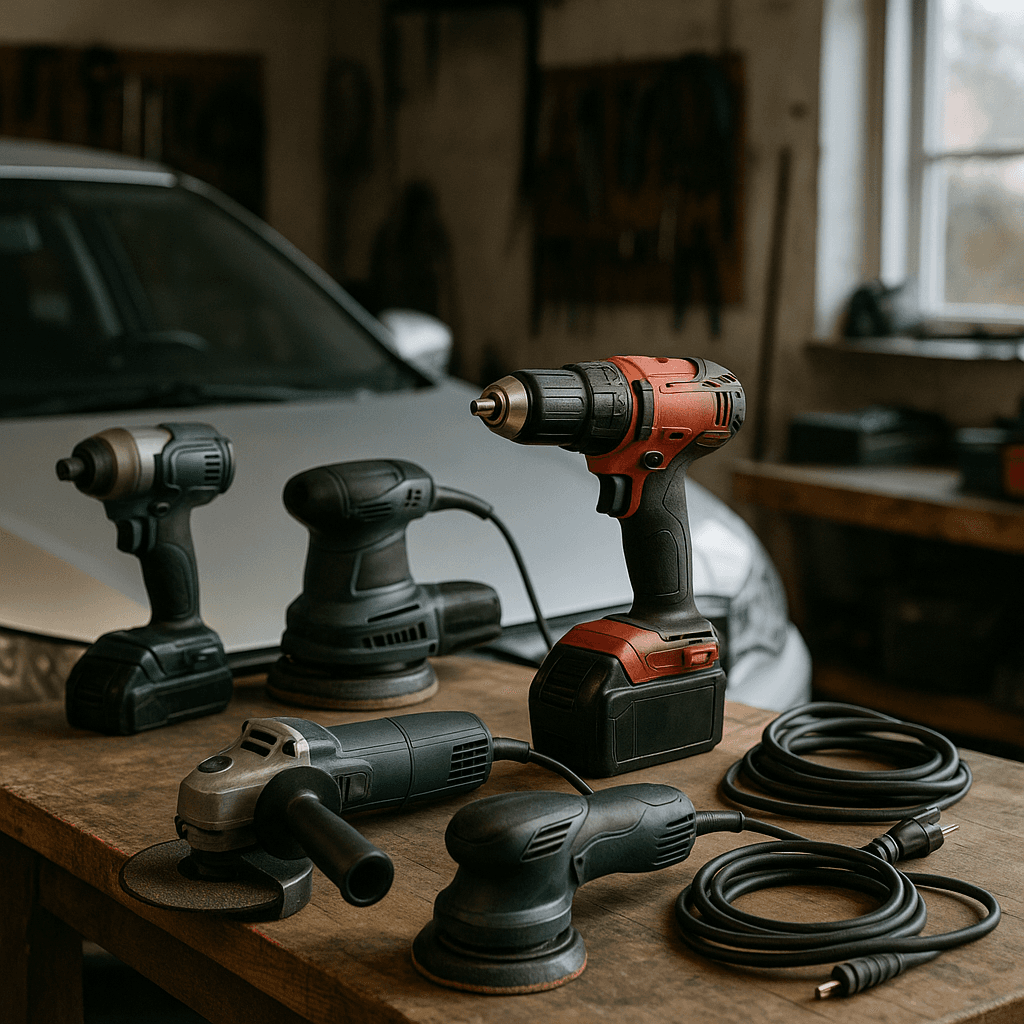

Top Power Tools for Automotive DIY for Indoor and Outdoor Use (Winter, December)

Tools Needed

Materials Needed

Safety Tips

- Always wear safety goggles to protect eyes from metal shavings and debris.

- Use gloves and ear protection when operating power tools.

- Secure your workpiece before using rotary tools to prevent accidents.

- Keep a fire extinguisher nearby when applying heat or using a torch.

- Avoid holding the heat gun too close to surfaces to prevent scorching or warping.

- Read tool manuals thoroughly before use to understand settings and safety precautions.

Before You Start / What to Know Up Front

If you've spent any time tinkering with cars, you know that having the right tools can make all the difference. I still remember the first time I tried to change my own oil; I nearly gave up because I didn’t have the right tools on hand. It was frustrating, but it taught me a valuable lesson about preparation and planning. This guide is for intermediate automotive DIYers who already have a few common tools and jack stands in their arsenal. We’ll dive into the top power tools you should consider for both indoor and outdoor automotive projects, especially with winter creeping in. Expect to learn why these tools matter, how to use them effectively, and the common pitfalls to avoid.

Method Overview

When it comes to automotive DIY, the right approach is essential. We’ll focus on power tools that enhance efficiency and precision. Power tools make tasks quicker, reduce physical strain, and often lead to better results compared to manual tools. The method we’ll take here combines safety, versatility, and practicality.

However, it’s not always the best fit for every situation. For instance, when I was working on my old Subaru in the cramped garage, I found that power tools were noisy and sometimes too bulky. If you’re in a tight space or need absolute silence, hand tools can be quieter and more precise. But for most automotive projects, especially in winter when you want to get the job done quickly, power tools can be a game-changer.

Deep Step Detail

Now, let's get into the nitty-gritty of the specific power tools that can elevate your automotive DIY game. Here’s a numbered breakdown of what you’ll need, along with tips on settings and options.

- Impact Wrench

An impact wrench is a must-have for loosening lug nuts or any stubborn bolts. I recommend a cordless model for ease of use, particularly one that offers at least 300 ft-lbs of torque. I use a 1/2-inch drive impact wrench from a reputable brand that has never let me down. When using it, make sure to set the torque to the manufacturer’s specifications to avoid damaging the fasteners. One common mistake I see is using too much torque on delicate parts; always err on the side of caution.

- Cordless Drill/Driver

A cordless drill is incredibly versatile. Use it for drilling holes or driving screws. For automotive work, a drill with adjustable speed settings is ideal. I usually set mine to a lower speed when starting to avoid stripping screws. Brands like DeWalt or Milwaukee offer excellent options that I’ve trusted for years. Make sure to keep a variety of drill bits handy, especially ones made for metal, as I’ve often found myself scrambling for the right bit mid-project.

- Rotary Tool

A rotary tool can be invaluable for cutting, grinding, or polishing. I’ve used mine to clean up rusted areas and even to cut out sections of exhaust pipes. Look for a model that has variable speed settings. Always remember to wear safety goggles; those tiny metal shavings can fly everywhere, and trust me, you don’t want one in your eye. One common oversight is forgetting to secure your workpiece; a loose piece can lead to accidents and poor cuts.

- Portable Generator

If you’re working outdoors during winter, a portable generator can keep your tools running smoothly. Make sure it’s rated for the power tools you plan to use. I’ve learned the hard way to avoid overloading it, which can trip the circuit. Always check the wattage requirements for your tools against what the generator can provide. A common mistake is using an old generator that can’t handle the load; regular maintenance can help prevent this issue.

- Heat Gun

A heat gun is excellent for tasks like removing old paint or loosening adhesive. I’ve used mine to help with stuck rubber gaskets. The key is to keep the heat gun moving to avoid damaging the surface underneath. If you're using it outdoors in winter, be cautious about how quickly the heat dissipates; the cold can make it less effective. One rookie mistake is holding it too close to the surface, which can scorch or warp materials.

Troubleshooting & Fix-ups

Even the best laid plans can go awry. Here are some common issues you might run into and how to handle them.

One frequent problem is stripped screws or bolts. If this happens, you can try using a screw extractor. Just be patient and make sure you're drilling straight down into the screw. If you don’t have an extractor, sometimes you can use a rubber band to help grip the screw head. Remember, if you feel resistance, don’t force it; you might end up damaging the surrounding material.

Another issue is when your impact wrench won't break a bolt loose. If that happens, try using penetrating oil and let it sit for a while. I’ve found that some bolts just need that extra time to loosen up. If it’s still stuck, apply heat with a torch (carefully!) to expand the metal, which can help break the bond. Just be sure to have a fire extinguisher nearby for safety.

If your drill battery isn't holding a charge, check the contacts for dirt or corrosion. Sometimes a good cleaning can revive it. If not, it might be time to invest in a new battery, or even a new drill if it’s an older model. A common mistake is neglecting battery maintenance; keeping your batteries clean can extend their life.

Common Mistakes & How to Avoid Them

As experienced DIYers, we’ve all made mistakes, and it’s often the same ones. One common error is not reading the manuals that come with your tools. Trust me, the first time I tried using a rotary tool without checking the manual, I ended up burning out the motor. Always take a few minutes to familiarize yourself with your tools and their specifications.

Another mistake is not using the right settings. Many DIYers jump right into using their power tools without adjusting the speed or torque settings. This can lead to stripped screws or even damage to the material you're working on. Always start slow and adjust as needed to achieve the best results.

Additionally, working without proper safety gear is a big no-no. Safety goggles, gloves, and ear protection are essential. I can't tell you how many times I’ve seen someone get careless and end up with a nasty cut or hearing damage. Safety gear is an investment in your well-being, so make sure to wear it every time.

Pro Tips & Lessons Learned

Over the years, I’ve picked up a few tips that can save you time, money, and frustration. One of my favorites is to keep a designated toolbox for your most-used power tools. This keeps everything organized and ensures you’re not scrambling to find what you need when you’re in the middle of a project.

Another tip is to label your tool chargers. It sounds simple, but when you have multiple chargers and batteries, it can get confusing. This little organization hack can save you from wasting time searching for which battery goes with which charger.

Don’t forget about maintenance. Regularly check your power tools for wear and tear. A little preventative care can extend the life of your tools. I always clean my tools after use and check for any loose screws or parts that might need tightening. I’ve learned that neglecting this step can lead to costly repairs down the line.

Also, invest in a good set of quality batteries. I’ve learned that cheaper batteries often don’t hold a charge as well and can lead to frustration mid-project. Look for brands with good reputations in the DIY community; this could save you headaches later.

Budget & Time Signals

When it comes to budgeting for power tools, expect to spend anywhere from $100 to $1,000 depending on the type and quality of tools you need. A basic impact wrench might cost around $100, while a high-end cordless drill could set you back $300 or more. The more specialized the tool, the higher the price tends to be.

Time-wise, if you’re just starting out, it might take you a few hours to get familiar with each tool. Plan for extra time when you’re using them for the first time. Once you’re comfortable, you’ll be able to complete projects much quicker. For winter projects, consider that cold weather can slow your work down, so factor that into your schedule. I’ve learned to allow for breaks to warm up my hands and tools when it’s really chilly outside.

When to Call a Pro

There are certain situations where it’s best to step back and call a professional. If you’re working on complex electrical systems or anything that involves major engine work, it’s often safer and more reliable to leave it to the experts. For example, if you’re dealing with serious engine issues or transmission work, those are areas where a pro can save you time and potential headaches.

Another sign it’s time to call a pro is if you feel out of your depth. If you’re unsure about how to proceed, don’t hesitate to seek help. Sometimes, a little consultation can save you from making costly mistakes. Trust your instincts; if something doesn’t feel right, it probably isn’t. I’ve learned that admitting when I need help can be just as important as knowing how to fix things myself.

Conclusion

Taking on automotive DIY projects can be incredibly rewarding, especially when you have the right tools in your corner. By equipping yourself with top power tools suited for both indoor and outdoor use, you’ll not only make your work more efficient but also enjoy the process more. Remember to stay safe, double-check your settings, and don’t be afraid to reach out for help when you need it.

So why not take a moment today to assess your tool collection? You might find that adding just one or two of these power tools can make a world of difference in your automotive projects. Happy DIYing!

Recommended Gear

Disclosure: As an Amazon Associate, we may earn from qualifying purchases at no extra cost to you.

Common Mistakes

- Not reading the manuals before using power tools.

- Using incorrect speed or torque settings leading to stripped screws or damaged materials.

- Neglecting to wear proper safety gear during projects.

- Overloading portable generators beyond their rated capacity.

- Holding the heat gun too close causing surface damage.

- Failing to maintain batteries leading to poor performance.